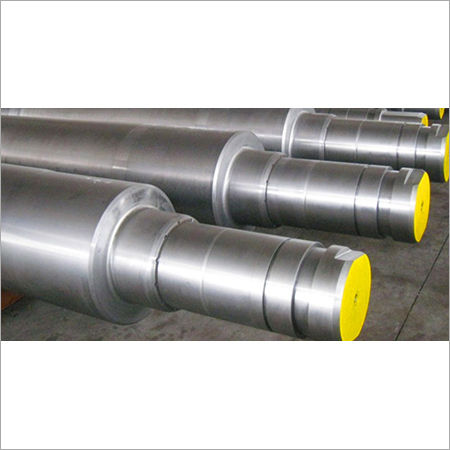

Industrial Spheroidal Graphite Iron Rolls

Product Details:

- Product Type Spheroidal Graphite Iron Rolls

- Material Iron

- Surface Finishing Polished

- Color Silver

- Click to view more

Industrial Spheroidal Graphite Iron Rolls Price And Quantity

- 20000 INR/Unit

- 1 Unit

Industrial Spheroidal Graphite Iron Rolls Product Specifications

- Polished

- Silver

- Iron

- Spheroidal Graphite Iron Rolls

Industrial Spheroidal Graphite Iron Rolls Trade Information

- 10000 Unit Per Month

- 6-8 Week

- Central America North America South America Eastern Europe Western Europe Middle East Asia Australia Africa

- All India

Product Description

Spheroidal Graphite Cast Iron Rolls are provided with high tensile strength to provide the best results in different manufacturing units. They are available in different sizes and lengths to meet the demands of the clients. Designed using high-grade cementite and nodular graphite, they are sure to provide satisfactory performance. The matrix structure is designed using Ferrito-Pearlitic, Pearlitic to Bainitic & Martensitic having varied contents of carbide and graphite.

Technical details

MATERIAL | HARDNESS (SH-D) | C% | MN% | SI% | CR% | NI% | MO% |

|---|---|---|---|---|---|---|---|

S.G. (PEARLITIC) | 40-50 | 3.00-3.30 | 0.30-0.60 | 1.50-2.30 | 0.015 MAX | 0.10 MAX | 0.30 MAX |

S.G. (PEARLITIC) | 50-60 | 3.00-3.30 | 0.30-0.60 | 1.50-2.30 | 0.015 MAX | 0.10 MAX | 0.30 MAX |

S.G. (PEARLITIC) | 60-70 | 3.10-3.50 | 0.50-1.00 | 1.30-1.80 | 0.015 MAX | 0.10 MAX | 0.30-0.80 |

S.G.(PEARLITIC) | 70-75 | 3.10-3.50 | 0.50-1.00 | 1.30-1.80 | 0.015 MAX | 0.10 MAX | 0.30-0.80 |

S.G. (ACICULAR) | 40-50 | 3.00-3.30 | 0.30-0.50 | 1.80-2.30 | 0.015 MAX | 0.80 MAX | 0.20 MAX |

S.G. (ACICULAR) | 50-60 | 3.00-3.30 | 0.30-0.50 | 1.80-2.30 | 0.015 MAX | 0.80 MAX | 0.20 MAX |

S.G. (ACICULAR) | 60-70 | 3.10-3.50 | 0.50-0.80 | 1.30-2.00 | 0.015 MAX | 0.80 MAX | 0.30-0.80 |

S.G. (ACICULAR) | 70-80 | 3.10-3.50 | 0.50-0.80 | 1.30-2.00 | 0.015 MAX | 0.80 MAX | 0.30-0.80 |